Acoustical Corrugated Ceiling Baffles

Suspended or Mounted Corrugated Acoustical Metal Baffles

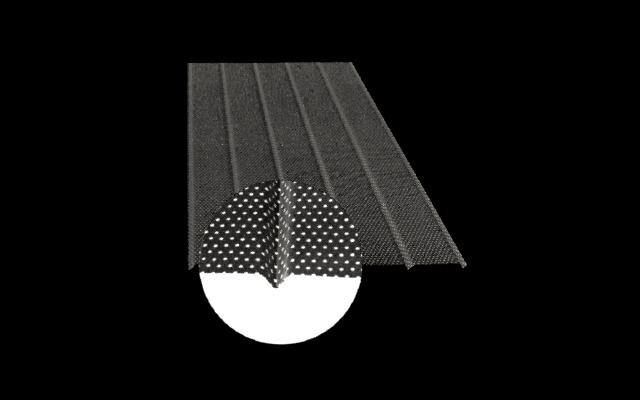

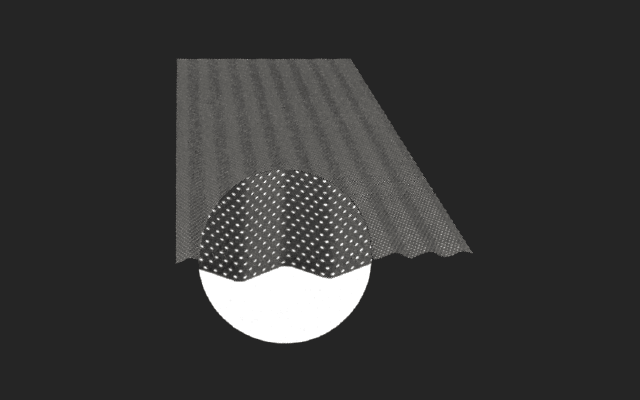

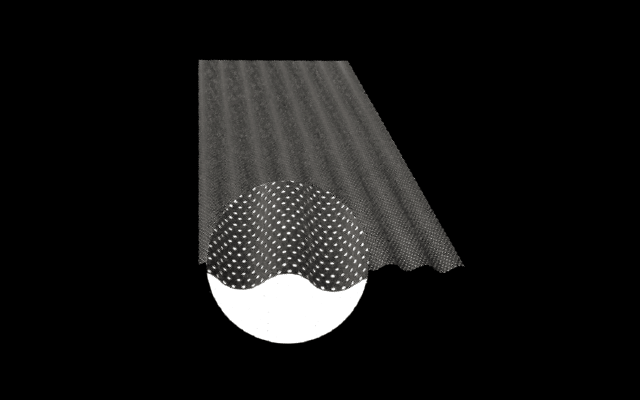

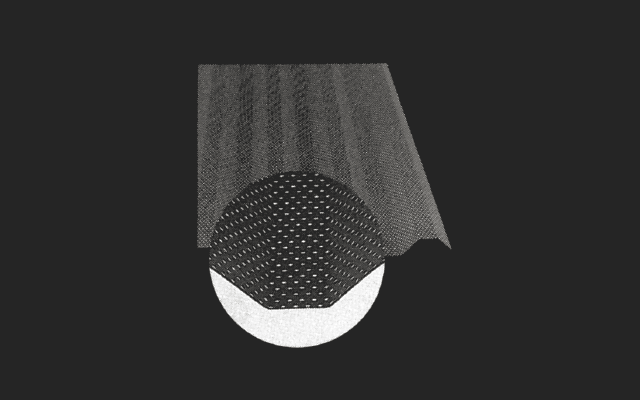

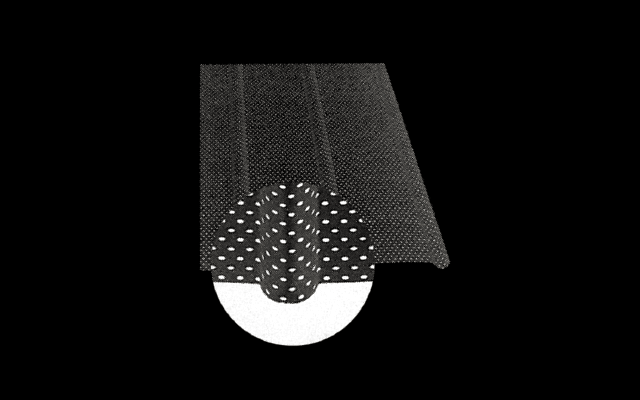

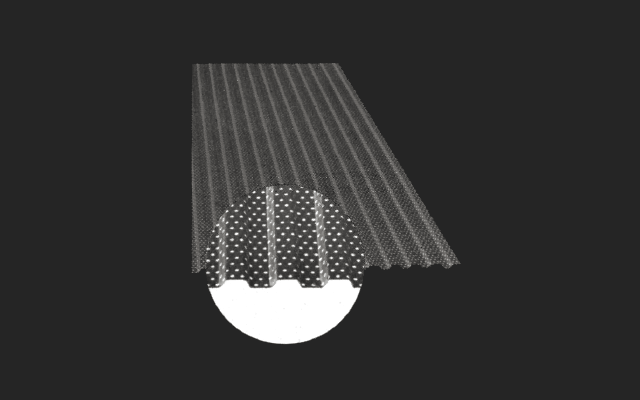

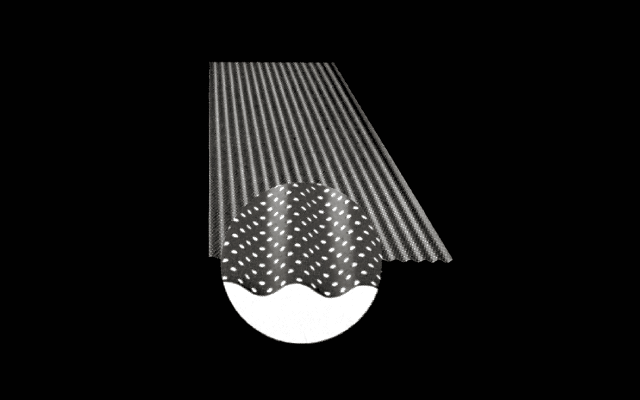

ALPRO® Ceiling Baffles are fully factory assembled, modular units of formed perforated metal skin, reinforced by structural components, containing encapsulated acoustical energy absorbing material.

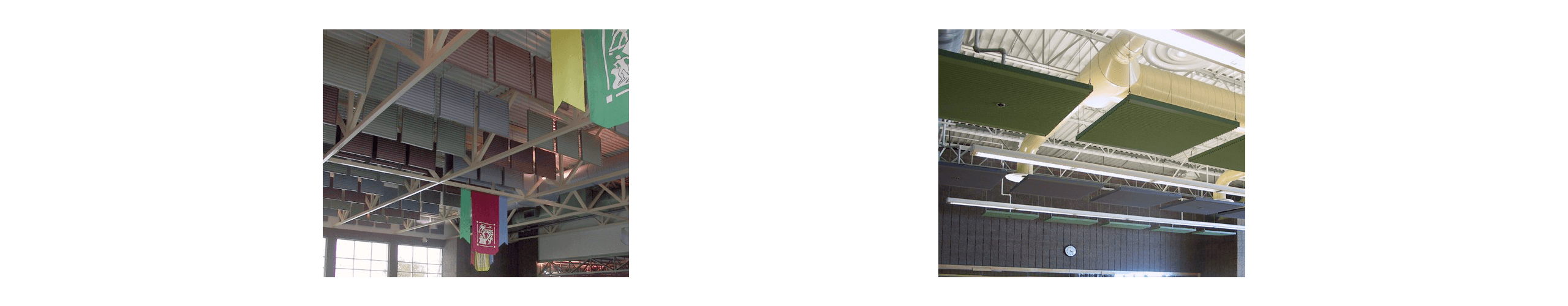

ALPRO® Ceiling Baffles may be hung vertically from the baffle side or end, or may be suspended horizontally like a cloud.

ALPRO® Ceiling Baffles provide a fast, cost-effective method for controlling reverberant noise in existing facilities, and are ideally suited for use in water treatment or other industrial facilities, natatoriums, hospitality areas, auditoriums - any space where reverberant noise is a problem.

ALPRO® Baffles are finished in your choice of standard or custom powder coat colors. Post fabrication powder coating assures total coverage of all surfaces for maximum protection from attack by moisture or airborne contaminants.

Features & Benefits

Metal Facing Options

- Aluminum – .032″ thickness in stucco-embossed or smooth surface

- Steel – 22, 24 or 26 gauge thickness, G-90 galvanized smooth surface

- Backer Panels are made of the same metal as the face and provide total encapsulation of the sound absorptive material and enhanced acoustical performance.

Baffle Configuration

- Perforated metal skins may be corrugated or flat

- Acoustical media is 2” thick, 1.5# density fiberglass encapsulated in PVC

- Baffles ship complete with appropriated mounting hardware

Frames

- Aluminum framing members provide the skeletal structure of the baffle.

- Standard baffle thickness is 2 inches, with custom thicknesses available from 1inch up to 6 inches.

Stabilizers

- Internal stabilizers are required for baffles over 48” long. The exact quantity and spacing of stabilizers will depend on material thickness and baffle design.

Without Stabilizer

Single Stabilizer

Double Stabilizer

Corrugation Patterns

Data on Acoustics

Finish Options

AAMA 2604 Powder Coating FinishesDownload PDF

Therapeutic Powder Coating Finishes Download PDF

Antimicrobial Finishes

Perforation Pattern

Green By Design

- Products contribute to LEED® certification

- In-House Finishes

- Biodegradable pre-treatment and powder coating (no phosphates)

- No hazardous waste

- No VOC’s

- No Heavy Metals

- Reference our sustainability page for more information.

Sound Absorbers

- 1.5# density x 2″ thick fiberglass, encapsulated in 1.5 mil thickness black polyethylene, fully sealed

- 1.5# density x 2″ thick fiberglass, encapsulated in 2.5 mil thickness low gloss black PVC, fully sealed

- 1.5# density x 2″ thick fiberglass, encapsulated in .75 mil thickness high gloss clear PVC, fully sealed

Note: Special sound absorbing materials may be used to accommodate baffles with custom thickness or special acoustical performance requirements. Please consult with the factory or your ALPRO® representative for availability.

Ceiling Baffle Installation Options

FLUSHMOUNT INSTALLATION OPTIONS

OFFSET MOUNT INSTALLATION OPTIONS

ANGLE MOUNT INSTALLATION OPTIONS

EYEBOLT INSTALLATION OPTIONS

HORIZONTAL TUNNEL MOUNT INSTALLATION OPTION

Acoustics

Laboratory tests to evaluate the sound absorption of ALPRO® baffles show results in a range from .90 to 1.15 when tested in accordance with ASTM C-423.

ALPRO® baffles are furnished with sound absorbing material already installed to assure predictable results, up to a perfect rating of NRC = 1.0 (1.0 Sabin/square foot), based on extensive product testing.

Actual acoustical performance of your baffle installation depends on a variety of factors including, baffle thickness, coverage area, mounting method, type and density of sound absorbing material utilized, room volume, and materials of building construction.

Consult with the factory or your ALPRO® representative to discuss your noise abatement challenges and for application suggestions to maximize acoustical performance for your project.