AAMA 2604 Powder Coating Finishes

Features & Benefits

Gordon AAMA 2604 Powder Coating Finishes provide the following advantages when compared to 50% PVDF liquid coating:

- Textures are available

- Broad gloss range

- Superior pencil hardness

- High abrasion and scratch resistance

- Higher impact resistance

- No VOCs emitted in pre-treatment process

- Factory finished

- Shorter lead-times

- Direct shipping from factory to jobsite

- EPA Compliant

- Endures acid exposure, even against Sulfuric Acid

Antimicrobial Surfaces

Gordon offers Metal Claddings, Acoustical Metal Panels and Ornamental Metals with Antimicrobial powder coating surfaces that can make a BIG IMPACT to help inhibit the growth of bacteria, mold, fungus and other harmful microorganisms.

Our environmentally friendly AAMA 2604 & 2605 powder coating Antimicrobial surfaces are available in a wide variety of colors to meet your design requirements.

Custom Colors

AAMA 2604 Powder Coatings can be color matched in any desired color of your choice. Simply send us a control sample of the specified color or provide the RAL # for color matching purposes.

Standard Colors

An array of commonly specified colors listed below are available for a faster turn time.

Finishes shown on this card may vary in color from an actual coating. Color samples, supplied on an aluminum panel, provide an actual representation of color, gloss, texture, and hue and are available upon request.

Technical Data

Properties | Test Method | 50% PVDF Liquid Coating | Super-Durable Polyester Powder Coating |

Textures | N/A | No | Yes |

Gloss Range (at 60°) | ASTM D523 | 5-25 | 5-90 |

Color Range¹ | N/A | Wide range of solids & metallics | Wide range of solids & metallics |

Smoothness (PCI Scale)² | PCI Tech Brief #20 | 5-8 | 5-8 |

Pretreatment, typ. ³ | N/A | Tri/Hex Valent Chrome | Chrome-Free dry-in-place |

Impact Resistance (deformation) | ASTM D2794 | 2.5 mm | 3.0 mm |

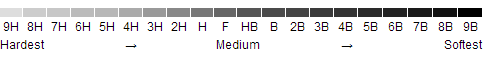

Pencil Hardness⁴ | ASTM D3363 | H | 3H |

Taber Abrasion (Wear Index)⁵ | ASTM D4060 | 140 | 100 |

Adhesion | ASTM D3359 | 5B | 5B |

100 Double Rubs MEK | PCI Method #8 | PASS | PASS |

Mandrel Bend | ASTM D522 | 1/4" | 1/4" |

Film Thickness | ASTM D7091 | 1.2 min | 2.0 min |

South Florida UV Resistance | Per AAMA 2604-21 | Up to 10 years Gloss retention: 30%+ Color Retention: △E <5.0 | Up to 10 years Gloss retention: 30%+ Color Retention: △E <5.0 |

Cyclic Corrosion | ASTM G85 | 1500 hrs. | 1500 hrs. |

Humidity Resistance | ASTM D2247 | 4000 hrs. | 4000 hrs. |

Footnote:

1Color ranges can be limited by high chromaticity which could facilitate the need for a clear top coat.

2PCI smoothness is directed by a set of 10 standard panels that vary in smoothness; 1 being the least smooth and 10 which represents nearly perfect smoothness.

3Pretreatment chemicals for PVDF coatings typically contains either trivalent or hexavalent chrome. Chrome is a heavy metal and extremely hazardous. Gordon powder coatings are applied over chrome-free pretreated substrates and exhibit excellent performance.

4Pencil Hardness Scale:

Environmental Policy

Our in-house finishing facility uses only water-soluble materials in our pre-treatment process. All overflow from this process is approved for introduction into our city water treatment plant without adverse impact to the environment. Gordon powder coat finishes are EPA compliant and contribute to the U.S. Green Building initiative.

Gordon’s environmental commitment is affirmed within our core Values, Beliefs, and Principles. Waste reduction and recycling are key elements of our business culture and are embraced by all Gordon team members.