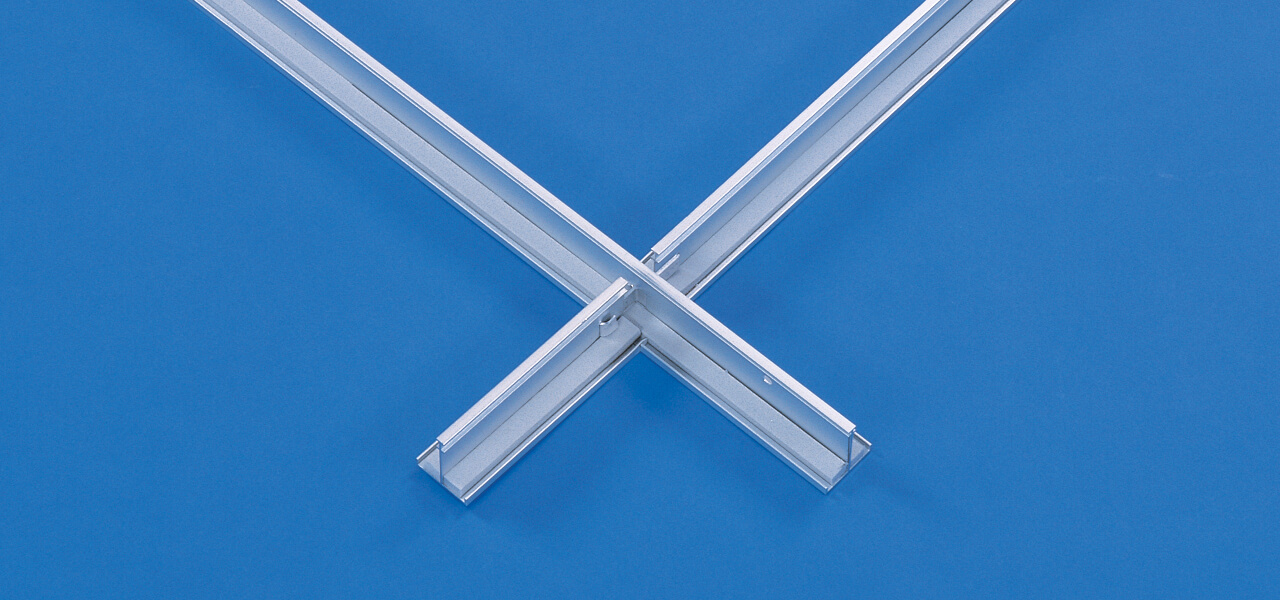

CG System

CG Grid is commonly used in such applications as food service, food processing, pharmaceutical and hospital industries. Designed with a 1-1/2″ face tee to support HEPA filter systems, CG systems are also available in other sizes, such as 15/16″ and 2″.

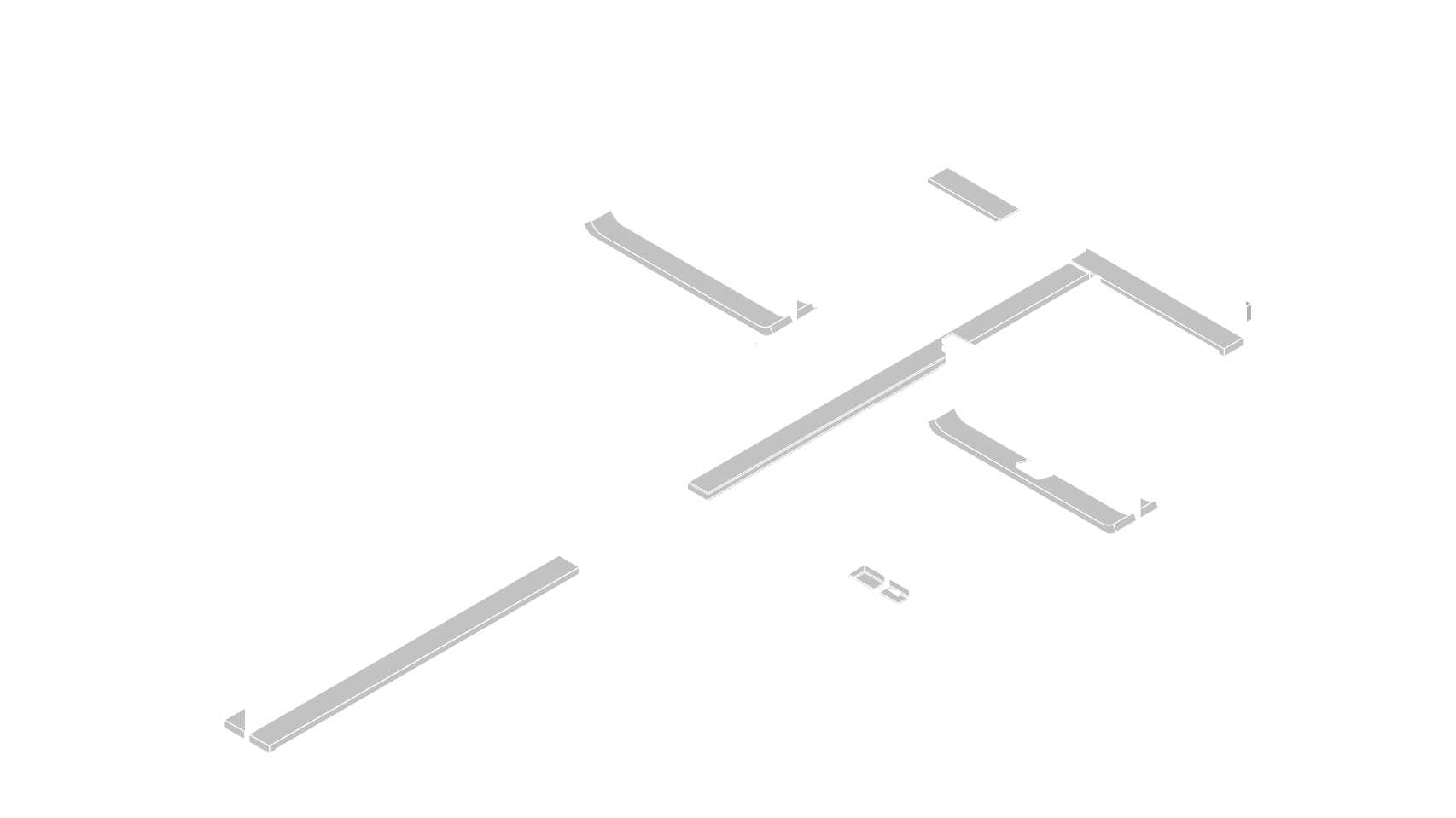

CG Profile Detail

CG Accessories

Finishes

CG systems are stocked in a clear satin anodized aluminum finish, which is recommended for harsh environments, and Pearl White Antimicrobial powder coat. Custom colors are also available.

Gasketing

The CG series factory-applied gasketing is a flexible, closed cell polyethylene foam which is crosslinked by means of a unique electron irradiation process. Gasketing is off white in color with excellent chemical resistance; 2# density per cubic foot.

- Passes fungus resistance test (Method 508.1 mill-std-810C)

- Flame-resistant (FMYSS #302 with burn rate of 4″ per minute)

- Shore Hardness (ASTM D-2240) on AA scale is 7; on OO scale is 51

Gasket Sizes

- CG-10 3/32″ x 3/8″

- CG-15 3/32″ x 15/32″

- CG-20 3/32″ x 15/32″

Custom gasketing is available. Contact our factory for gasket specifications.

Compatibility

Contact our factory for information concerning filter and light fixture compatibility as well as load data and other technical information.

Quick Shop Program

- 10,000 SF room

- 20,000 SF room for CG-15 powder coat white (PDR-60103 Pearl White)

- Available in full cartons only

- Material will ship within 5 business days

CG Load Table

System Type | Web Height | Span Hanger Wire Spacing | Spacing of Main Tees | Applied Load | ASTM |

CG-20 | 2" | 48" | 24" | 10.2 | Heavy Duty |

CG-15 | 1-1/2" | 24" | 48" | 14.7 | Heavy Duty |

CG-10 | 1-1/2" | 42" | 48" | 4.8 | Heavy Duty |

CG Parts Specifications

Part Number | Description | A | B | Length | Weight per linear ft. w/gasket | Pieces per carton w/gasket | Linear feet per carton |

CG-10-MT | Main Tee | 1-1/2" | 15/16" | 12' | 0.18 | 40 | 480 |

CG-15-MT | Main Tee | 1-1/2" | 1-1/2" | 12' | 0.24 | 24 | 288 |

CG-20-MT | Main Tee | 2" | 2" | 12' | 0.31 | 16 | 192 |

CG-10-48 | Cross Tee | 1-1/2" | 15/16" | 4' | 0.18 | 120 | 480 |

CG-10-24 | Cross Tee | 1-1/2" | 15/16" | 2' | 0.18 | 120 | 240 |

CG-15-48 | Cross Tee | 1-1/2" | 1-1/2" | 4' | 0.24 | 72 | 288 |

CG-15-24 | Cross Tee | 1-1/2" | 1-1/2" | 2' | 0.24 | 72 | 144 |

CG-20-48 | Cross Tee | 2" | 2" | 4' | 0.31 | 48 | 192 |

CG-20-24 | Cross Tee | 2" | 2" | 2' | 0.31 | 48 | 96 |

CG-WA-1 | Wall Angle | 3/4" | 3/4" | 12' | 0.09 | 40 | 480 |

CG-WA-2 | Wall Angle | 15/16" | 15/16" | 12' | 0.12 | 40 | 480 |

CG-WA-4 | Wall Angle | 1-1/2" | 15/16" | 12' | 0.16 | 30 | 360 |

CG-WA-4S | Wall Angle | 15/16" | 1-1/2" | 12' | 0.16 | 30 | 360 |

CG-WA-10G | Wall Angle | 1-1/2" | 15/16" | 12' | 0.19 | 30 | 360 |

CG-WA-15 | Wall Angle | 1-1/2" | 1-1/2" | 12' | 0.22 | 30 | 360 |

CG-WA-20 | Wall Angle | 2" | 2" | 12' | 0.30 | 30 | 360 |

RG System

Applications include pharmaceutical, food processing, and hospital industries. The RG system differs from the CG system in that the 1-1/2″ extruded aluminum face tee is designed with an 1/4″ upturned flange and provides a sharp architectural detail. Panels or filters contact the gasket first to complete a seal prior to settling on the tee flange.

RG Profile Detail

RG Accessories

Finishes

- Clear satin anodized aluminum for harsh environments

- Pearl White Antimicrobial powder coat

- Optional antimicrobial powder coat

- Custom finishes

Gasketing

The standard RG Series gasket is a factory applied, 1/4″ x 1/2″ closed cell PVC, gray in color, with small cells and a smooth surface. Gaskets are available with adhesive on one or both sides; polyvinyl, neoprene, polyethylene; anti-bacterial, and flame retardant. Call Gordon if custom gaskets are required.

Gasket Sizes

- Passes fungus resistance test (Method 508.1 mill-std-810C)

- Flame-resistant (FMYSS #302)

- Shore Hardness (ASTM D-2240) on AA scale is 7; on OO scale is 51

- 8# density per cubic foot

- U.S.D.A. approved

Filter Compatibility

RG systems are compatible with all major filter manufacturers.

Light Fixture Compatibility

RG systems require fixtures designed specifically for cleanroom applications.

Custom Panels

Custom .032″ aluminum panels are manufactured in all sizes to allow for non-standard module sizes, fill-in perimeter panels and sprinkler panels.

RG Load Table

System Type | Web Height | Span Hanger Wire Spacing | Spacing of Main Tees | Applied Load | ASTM |

RG-15 | 1-3/4" | 48" | 24" | 8.9 | Heavy Duty |

RG Parts Specifications

Part Number | Description | A | B | Length | Weight per linear ft. w/gasket | Pieces per carton w/gasket | Linear feet per carton |

RG-15-MT4 | Main Tee | 1-3/4" | 1-1/2" | 12' | 0.31 | 16 | 192 |

RG-15-MT2 | Main Tee | 1-3/4" | 1-1/2" | 12' | 0.31 | 16 | 192 |

RG-15-48CN | Cross Tee | 1-3/4" | 1-1/2" | 4' | 0.31 | 48 | 192 |

RG-15-48NN | Cross Tee | 1-3/4" | 1-1/2" | 4' | 0.31 | 48 | 192 |

RG-15-24 | Cross Tee | 1-3/4" | 1-1/2" | 2' | 0.31 | 48 | 96 |

RG-WA-48 | Wall Angle | 1-1/2" | 3/4" | 12' | 0.23 | 24 | 288 |

RG-WA-24 | Wall Angle | 1-1/2" | 3/4" | 12' | 0.23 | 24 | 288 |

Green By Design

- Products contribute to LEED® certification

- In-House Finishes

- Biodegradable pre-treatment and powder coating (no phosphates)

- No hazardous waste

- No VOC’s

- No Heavy Metals

- Reference our sustainability page for more information.