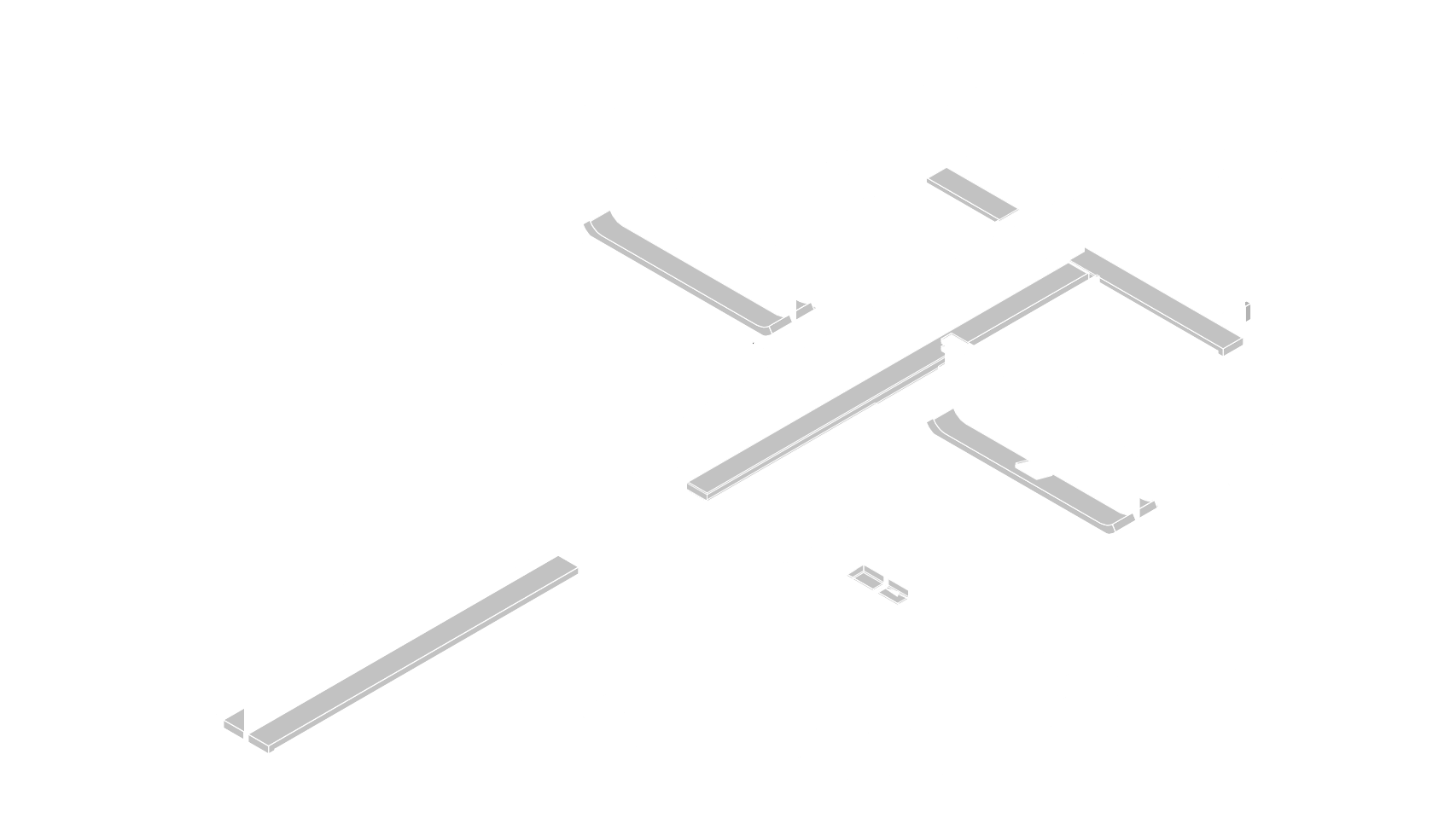

Gordon Cleanroom products LR-15 ceiling system is designed primarily for use in pharmaceutical, hospital and food service cleanroom applications. Extruded aluminum grid members have a 1/4″ upturned flange to provide a cleanable edge that also conceals the gasket. Blank panels, filters or other ceiling components first contact the gasket to create an airtight seal prior to settling on the tee flange. Grid components are fabricated of extruded aluminum for maximum structural integrity and corrosion resistance, even in harsh environments. Aluminum assembly clips simplify installation and require no special tools to attach grid components.

Optional hold-down clips are available to secure blank panels in the grid.

NOTE: Gordon does not recommend grid systems for use with fan powered modules (FFU’s). Consider Gordon rod-suspended grid systems for FFU applications.

LR-15

Extruded Grid Components

- 6063 T-5 aluminum alloy

Finishes

- Clear satin anodized for harsh environments

- Pearl White Antimicrobial powder coat

Factory Applied Gaskets

- Closed-cell PVC, 8# density

- U.S.D.A. approved

- Fungus-resistant (Method 508.1 Mil Std 810-C)

- Flame-resistant (FMYSS #302; burn rate 4” per minute)

- Color: Light Grey

- Contact factory for custom gasket availability

Grid Layout Modules

- 2′ x 4′

- 2′ x 2′

- Metric or custom module sizes can be provided

LR Application Guidelines

Appropriate for cleanrooms designed to:

- ISO-7 (Class 10,000) or higher

- Use ducted terminal filter modules

- Use cleanroom standard size filters and light fixtures

Suspension And Load Data

- Minimum 12 gauge hanger wire (furnished by others)

- Hanger Wire Spacing:

- 4’ o.c. for panels up to 5 lbs. per square foot

- At all 4 corners of filter module and light fixture location

- Load test recommendations outlined in the brochure should not be exceeded, nor should the components be deflected more than 1/360th of their span.